Trabajando diariamente con compuestos NBR en la fábrica de espuma de caucho de Hairui aquí en China, hemos visto avances significativos en PVC-NBR (Cloruro de polivinilo-caucho de nitrilo butadieno) se mezcla a lo largo de los años. Si bien muchos fabricantes luchan por optimizar la mezcla, nuestro equipo técnico ha dedicado innumerables horas a perfeccionar estos materiales. Esto es lo que hemos aprendido sobre estos elastómeros termoplásticos únicos.

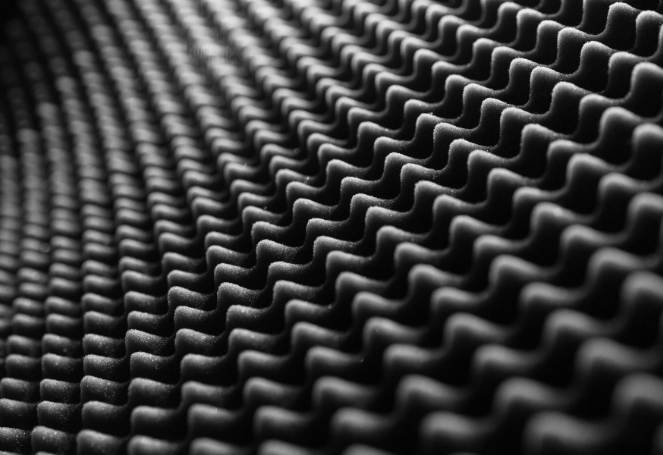

Mire la mayoría de las mezclas de polímeros bajo un microscopio y verá fases distintas. PVC-NBR es diferente. Estas mezclas muestran una estructura monofásica que es bastante rara en el mundo de los polímeros. Hemos probado numerosas muestras en nuestro laboratorio en hairuirubber.com y esta característica única aparece constantemente en nuestros análisis.

La mayoría de las mezclas de elastómeros se separan como el aceite y el agua. No PVC-NBR. El material forma una fase unificada, lo que explica por qué se procesa de manera tan diferente a los TPE estándar. En nuestras instalaciones de producción, esto significa que podemos lograr una mejor consistencia y menos defectos.

Los grupos nitrilo del NBR y los átomos de cloro del PVC se parecen entre sí, químicamente hablando. Forman fuertes enlaces intermoleculares que mantienen estable la mezcla. Hemos visto esta estabilidad de primera mano cuando realizamos pruebas de alta temperatura en nuestro laboratorio.

En nuestra fábrica de espuma de caucho, procesamos estas mezclas a través de extrusoras y máquinas de moldeo por inyección estándar. Manejan bien múltiples ciclos de procesamiento, lo que ahorra tiempo y costes de material. Pero tenga cuidado con las temperaturas de procesamiento: hemos descubierto que permanecer por debajo de 180 °C generalmente da los mejores resultados.

Lograr una vulcanización correcta puede resultar complicado. Mediante prueba y error, hemos aprendido que la velocidad de corte es más importante de lo que la mayoría de la gente piensa. Nuestros operadores generalmente comienzan con velocidades más bajas y las ajustan según la respuesta del material.

Estas mezclas se recuperan, literalmente. Hemos realizado pruebas de compresión a largo plazo que muestran propiedades de recuperación notables. Un cliente de automoción cambió a nuestros servicios de proveedor de espuma NBR después de que su material anterior siguiera teniendo deformaciones permanentes.

Nuestras pruebas muestran una sólida resistencia a:

Los datos del mundo real de nuestros clientes respaldan esto. Un fabricante de cables informó que no había degradación después de 18 meses de exposición en el campo.

Encontrar el punto óptimo entre rigidez y flexibilidad es difícil. Nuestra experiencia como fabricante de caucho espuma muestra que las mezclas de PVC-NBR alcanzan bien este equilibrio.

A la gente de alambres y cables les encantan estas cosas. Funciona muy bien para revestimiento y aislamiento. Uno de nuestros clientes habituales procesa estos materiales a velocidades de hasta 200 metros por minuto sin problemas.

Usos automotrices

Las piezas de automóvil reciben una paliza. Es por eso que varios proveedores automotrices importantes obtienen su caucho NBR de Hairui Rubber. Estos materiales soportan las temperaturas debajo del capó y la exposición constante al aceite sin sudar.

Usos industriales generales

Nuestra fábrica de espuma de caucho suministra periódicamente materiales para:

Integración de nanomateriales

Hairui y nuestros socios de I+D están probando actualmente adiciones de nanoarcilla a estas mezclas. Los primeros resultados parecen prometedores: mejores propiedades de barrera sin sacrificar la flexibilidad. Pero todavía queda trabajo por hacer en las técnicas de dispersión.

Pasos de fabricación ecológica

Las preocupaciones medioambientales importan. Estamos trabajando en:

Superando los límites del rendimiento

Nuestro laboratorio nunca deja de realizar pruebas. Áreas de enfoque actuales:

Después de años como proveedor y fabricante de gomaespuma, conocemos estos materiales por dentro y por fuera. Las mezclas de PVC-NBR resuelven problemas reales en aplicaciones exigentes. No son perfectos para todo (ningún material lo es), pero cuando se necesita esa combinación específica de procesabilidad y rendimiento, son difíciles de superar.

La naturaleza monofásica de estas mezclas les confiere ventajas únicas. En Hairui Rubber, hemos optimizado nuestros procesos de producción para aprovechar al máximo estas características. Cada lote que producimos pasa por pruebas rigurosas para garantizar que cumple tanto con nuestros estándares como con sus especificaciones.

Hairui Insulation representa la creciente presencia de China en el sector mundial de fabricación de aislamientos. Como fabricante certificado ISO 9001:2015, Hairui demuestra compromiso con los estándares de calidad internacionales en sus procesos de producción. Nuestras instalaciones de fabricación se especializan en diversas soluciones de aislamiento, incluidos productos técnicos como espuma de polietileno de celda cerrada, materiales a base de caucho, NBR, EPDM, eva productos de aislamiento, así como soluciones de aislamiento tradicionales como lana de vidrio y lana cerámica.

¿Necesita ayuda para determinar si las mezclas de PVC y NBR se adaptan a su aplicación? Nuestro equipo técnico se ocupa cada día de estos materiales. Déjanos una línea aquí - Siempre estamos felices de compartir lo que hemos aprendido a lo largo de los años.